Customer stories

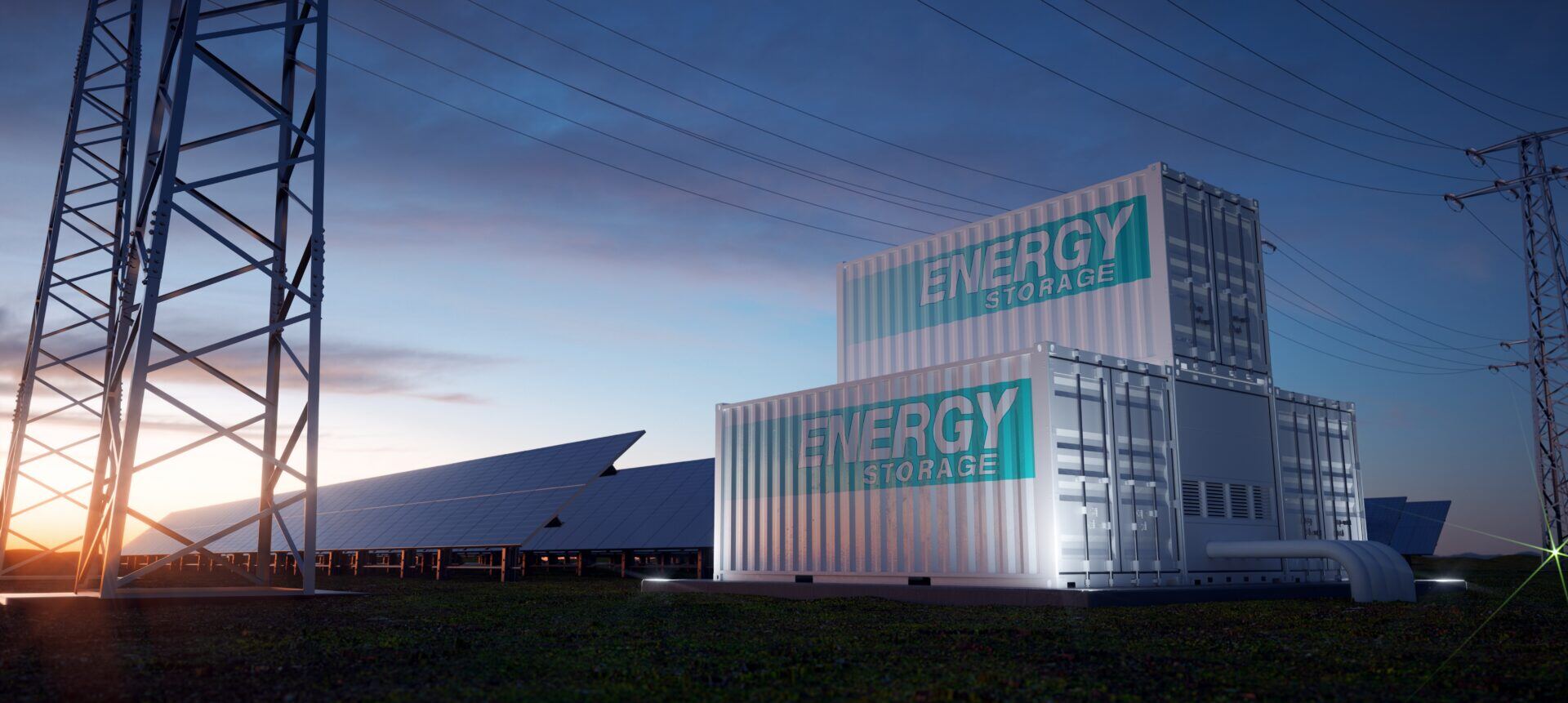

We provide the world’s most comprehensive product suite — purpose-built for renewable energy assets.

- Filters

Sort

Optimize assets, maximize revenue, and grow your portfolio with Unity

Ready to experience the future of renewable energy management?